LVDS (Low-Voltage Differential Signaling) in automotive applications is a critical technology for high-speed, noise-resistant data transmission. Here’s a structured overview:

Key Features of LVDS:

- Noise Immunity: Uses differential signaling to cancel electromagnetic interference (EMI), crucial in the electrically noisy automotive environment.

- Bajo consumo: Operates at low voltage (≈1.2V), reducing energy use, important for electric vehicles.

- High-Speed Data Transfer: Supports bandwidths up to several Gbps, enabling real-time video and sensor data transmission.

Applications in Automotive Systems:

- Infotainment & Displays: Connects head units to high-resolution screens (dashboards, center consoles) with minimal EMI.

- ADAS & Cameras: Transmits video from surround-view, backup, and lane-monitoring cameras to processing units.

- Sensor Networks: Facilitates data transfer from LiDAR, radar, and cameras for autonomous driving systems.

- SerDes (Serializer/Deserializer) Integration: Reduces wiring complexity by converting parallel data to serial LVDS streams, critical for weight and cost savings.

Automotive-Specific Considerations:

- Robustness: Components meet stringent standards (e.g., AEC-Q100) for temperature extremes, vibration, and humidity.

- EMC Compliance: LVDS’s noise resilience helps pass automotive electromagnetic compatibility tests.

- Escalabilidad: Evolves to support increasing bandwidth demands from advanced features like 4K displays and autonomous systems.

Complementary Technologies:

- FPD-Link: A serialized LVDS interface for video, reducing wire count in displays and cameras.

- Automotive Ethernet: Handles broader data communication, while LVDS focuses on high-speed physical-layer links.

Advantages Over Alternatives:

- Replaces older interfaces (RGB, LVCMOS) with superior EMI performance.

- More efficient than parallel wiring, critical for reducing harness weight and complexity.

Challenges:

- Ensuring signal integrity over long cables in harsh conditions.

- Adapting to evolving bandwidth needs without sacrificing reliability.

Conclusión:

LVDS is indispensable in modern vehicles, enabling reliable, high-speed data transmission for safety, infotainment, and autonomous driving systems. Its noise immunity, efficiency, and integration with SerDes make it a cornerstone of automotive electronics.

Expanding LVDS Applications: Customized Automotive Solutions

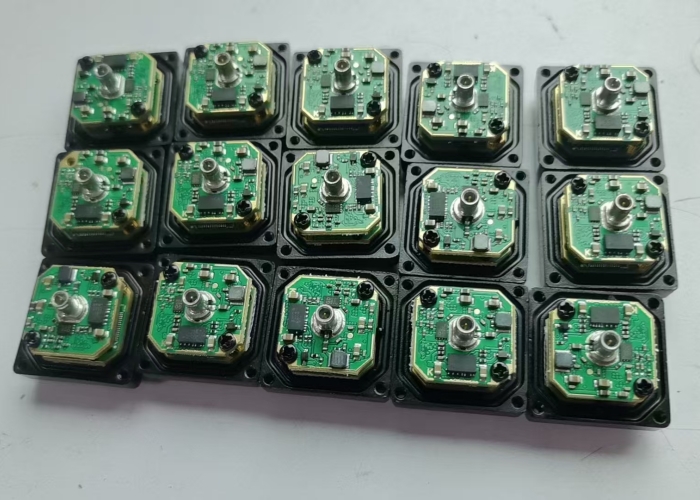

As automotive technology advances, LVDS-based rearview cameras are becoming increasingly critical for safe, high-resolution backup and parking assistance systems. LVDS ensures reliable transmission of real-time video feeds even in challenging environments, making it the preferred interface for next-generation camera systems.

Our Expertise:

At DT-camera, we specialize in developing and customizing LVDS-based rearview camera solutions tailored to diverse vehicle models and OEM requirements. Our services include:

- Vehicle-Specific Integration: Custom LVDS camera designs optimized for unique form factors, power budgets, and connectivity needs.

- High-Performance Imaging: Support for HD/4K resolution with low latency, ensuring compliance with automotive safety standards.

- Soluciones escalables: Adaptable to evolving ADAS architectures, including multi-camera systems and sensor fusion platforms.

Why Partner With Us?

- Proven Expertise: Decades of experience in automotive-grade LVDS system design.

- Asistencia integral: From prototyping to mass production, with rigorous EMI/EMC testing.

- Eficiencia de costes: Streamlined designs reduce wiring complexity and assembly costs.

Contact Us Today to discuss how our LVDS camera solutions can enhance your vehicle’s safety and performance. Let’s innovate together!